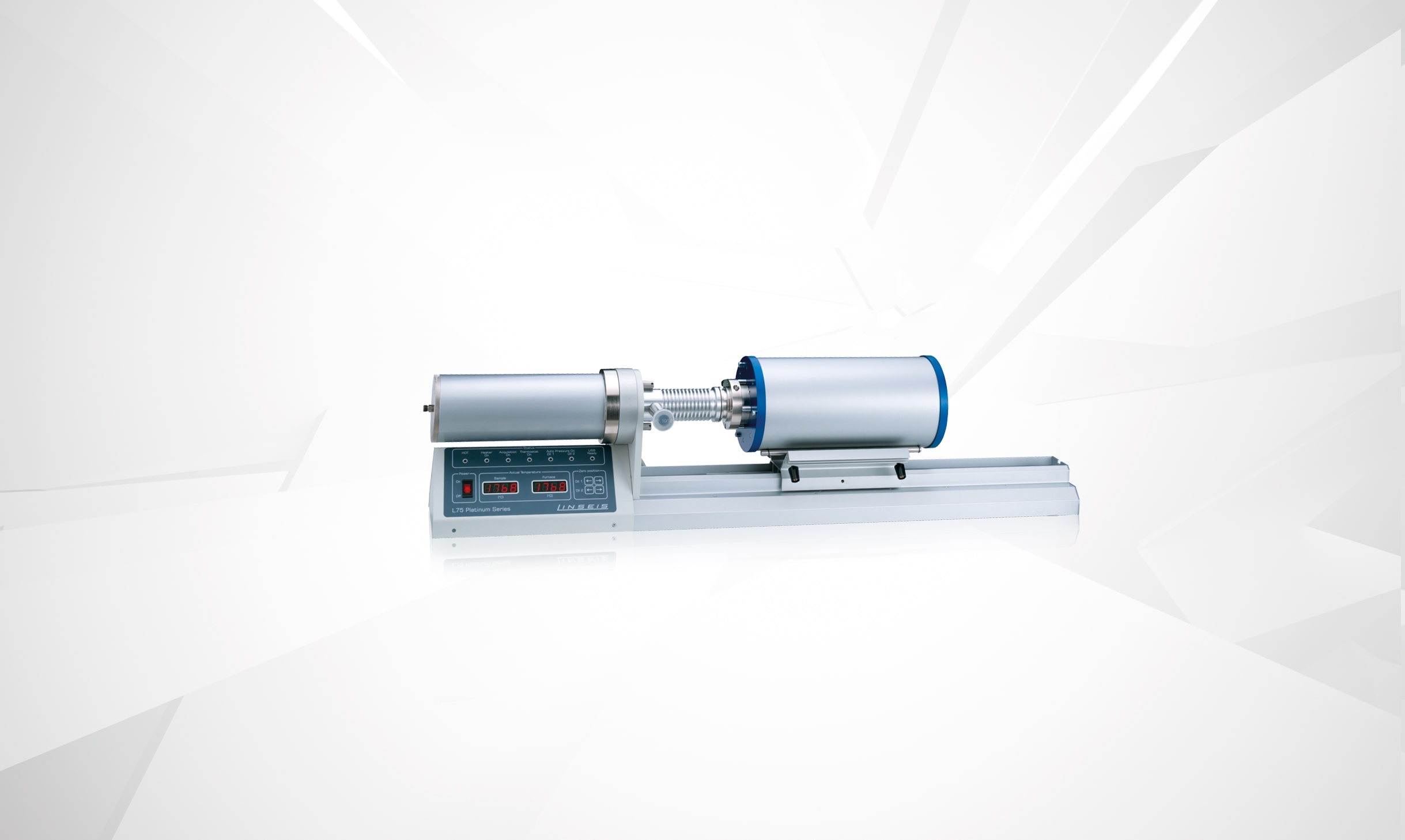

L75 PT Horizontal

Research Dual- and Differential Dilatometer series

Description

On point

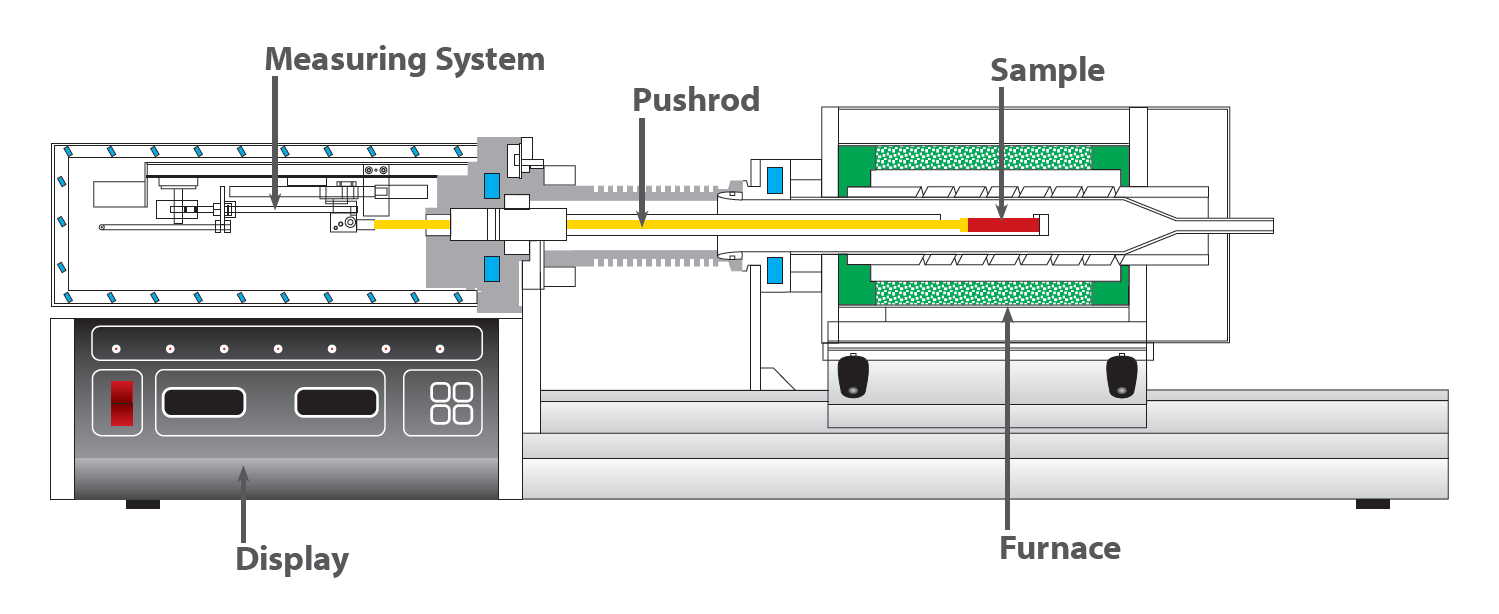

The horizontal Dual- and differential- Dilatometer (DIL) series L75H was developed to meet the demands of the academic community and research laboratories worldwide. With this system, thermal expansion behavior of solids, liquids, powders and pastes for a variety of applications can be precisely determined. The unique design of this system guarantees highest precision, reproducibility and accuracy. This line of Dilatometers is capable of performing measurements under vacuum, oxidizing and reducing atmospheres.

This system can be ordered in a single, dual or differential version for even higher precision or sample throughput. Optionally the mechanical and electronic components of the dilatometer can be separated to allow measurements in a glove box.

With our automatic pressure control, the contact pressure can be continuously varied between 10 and 1000mN, depending on the application. This feature continuously controls the selected contact pressure throughout expansion and/or shrinkage of the sample.

The following physical properties can be measured:

CTE, Linear Thermal Expansion, Alpha Physical, Sintering Temperature, Phase Transformations, Softening Points, Decomposition Temperatures, Glass Transition Temperatures.

You are interested in a instrument?

You need more information?

Contact us today!

Specifications

Black and white

| Model | DIL L75 Horizontal |

|---|---|

| Temperature range: | -180 up to 2800°C |

| LVDT: | |

| Delta L resolution: | 0,03 nm |

| Measuring range: | +/- 2500 µm |

| Contact force: | 10 mN up to 1 N |

| Optical Encoder: | |

| Delta L resolution: | 0,1 nm |

| Measuring range: | +/- 25000 µm |

| Automatic sample length detection: | yes |

| Kraftmodulation: | yes |

| Force modulation: | yes |

| Contact force: | 10 mN up to 5N |

| Multiple furnace configuration: | up to 2 furnaces |

| Motorized furnace operation: | optional |

| – (Unsichtbar, siehe EXTRA CLASS NAME unten) – | – (Unsichtbar, siehe EXTRA CLASS NAME unten) – |

|---|---|

| Gas dosing: | manual gas dosing or mass flow controller 1/3 or more gases |

| Contact force adjustment: | included |

| Single/double dilatometer: | optional |

| Softening point detection: | included |

| Density determination: | included |

| L-DTA: | optional (up to 2000°C) |

| Rate controlled sintering (RCS): | included |

| Thermal library: | included |

| Electric thermostatization of measuring head: | included |

| Low temperature options: | LN2, Intra |

| Vacuum tight design: | yes |

| Automatic evacuation system: | optional |

| OGS oxygen getter system: | optional |

Furnace & Accessories

Possible furnace options:

- L75/H 500LT -180°C up to +500°C

- L75/H 700LT -180°C up to +700°C

- L75/H 1000 RT up to 1000°C

- L75/H 1400 RT up to 1400°C

- L75/H 1550 RT up to 1600°C

- L75/H 2000 RT up to 2000°C

Accessories:

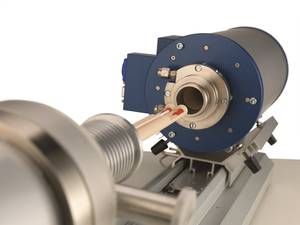

- Different types (designs/materials) of sample holders

- Vernier calipers for online input of the sample length

- Selection of manual, semi-automatic and automatic (MFC), Gas Boxes for up to 4 gases

- Instruments for sample preparation

- Software Option for rate controlled sintering (RCS)

- Various rotary and turbo-molecular pumps

- Possibility to operate under H2

Software

All LINSEIS thermo analytical instruments are PC controlled. The individual software modules exclusively run under Microsoft® Windows® operating systems. The complete software consists of 3 modules: temperature control, data acquisition and data evaluation. The 32 bit software incorporates all essential features for measurement preparation, execution, and evaluation of a Dilatometer measurement. Thanks to our specialists and application experts, LINSEIS was able to develop comprehensive easy to understand user friendly application software.

DIL-Features

- Glass transition and softening point evaluation

- Softening point detection with automatic software controlled system shut down

- Display of relative/absolute shrinkage or expansion curves

- Presentation and calculation of technical / physical expansion coefficient

- Rate Controlled Sintering (RCS) Software

- Sinter process evaluation

- Semiautomatic evaluation functions

- Several system correction features

- Automatic zero point adjustment

- Automatic software controlled sample pressure adjustment

General features

- Program capable of text editing

- Data security in case of power failure

- Thermocouple break protection

- Repetition measurements with minimum parameter input

- Evaluation of current measurement

- Curve comparison up to 32 curves

- Storage and export of evaluations

- Export and import of data ASCII

- Data export to MS Excel

- Multi-methods analysis (DSC TG, TMA, DIL, etc.)

- Zoom function

- 1 and 2 derivation

- Programmable gas control

- Statistical evaluation package

- Free scaling

Applications

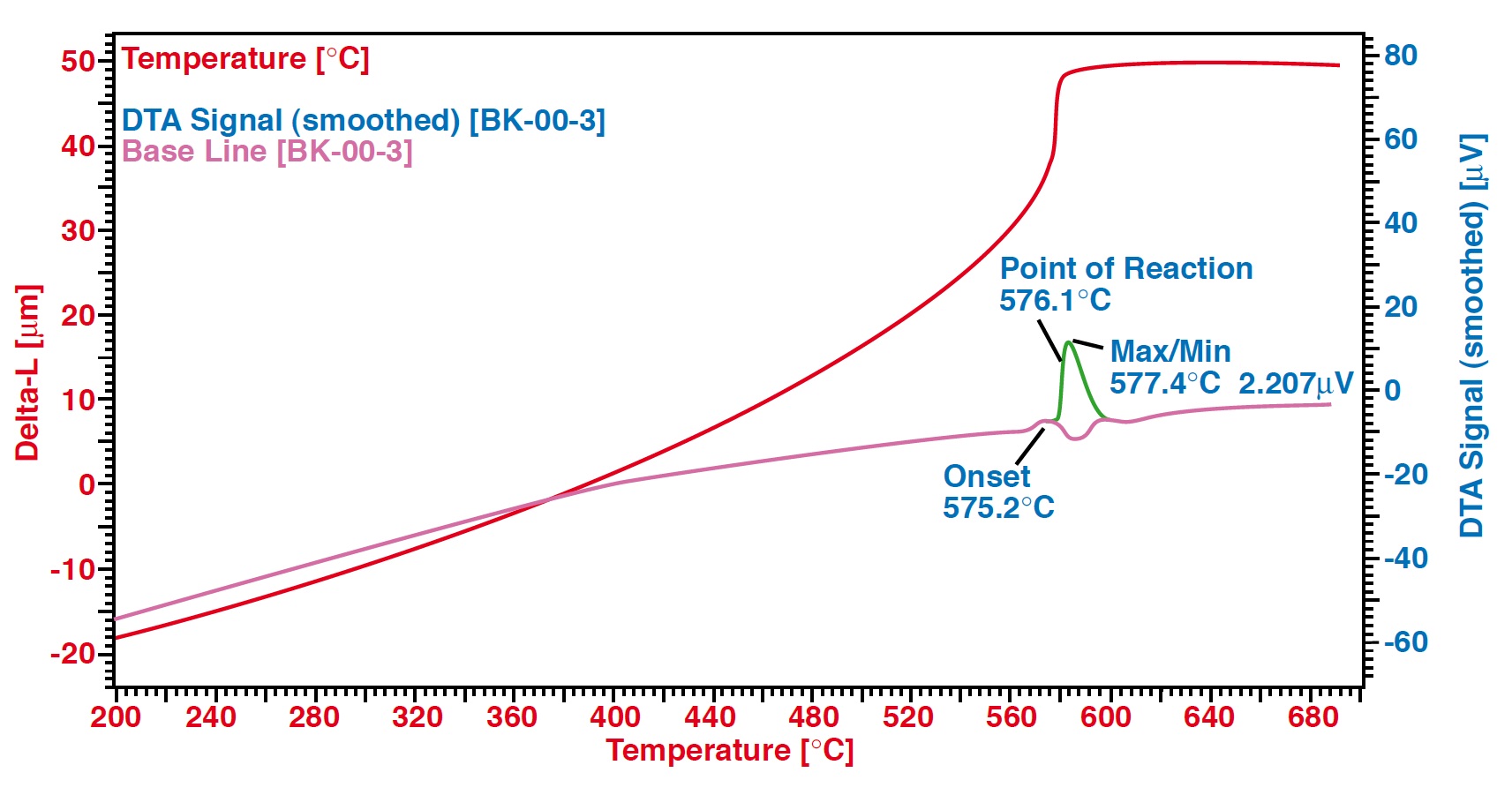

Application example: Rock – Crystal (Calculated DTA)

The thermal expansion of rock crystal can be easily evaluated with the L75 Dilatometer. The additional DTA feature enables an in depth view of the thermal behavior of the material. The DTA measurement is a mathematical routine based on the sample temperature. Exo- and endothermic effects influence the change of the sample temperature during the dynamic heating or cooling cycle. At app. 575°C the phase transition from takes place. The deviation of the measured temperature from the literature value (574°C) can be used for a temperature calibration.

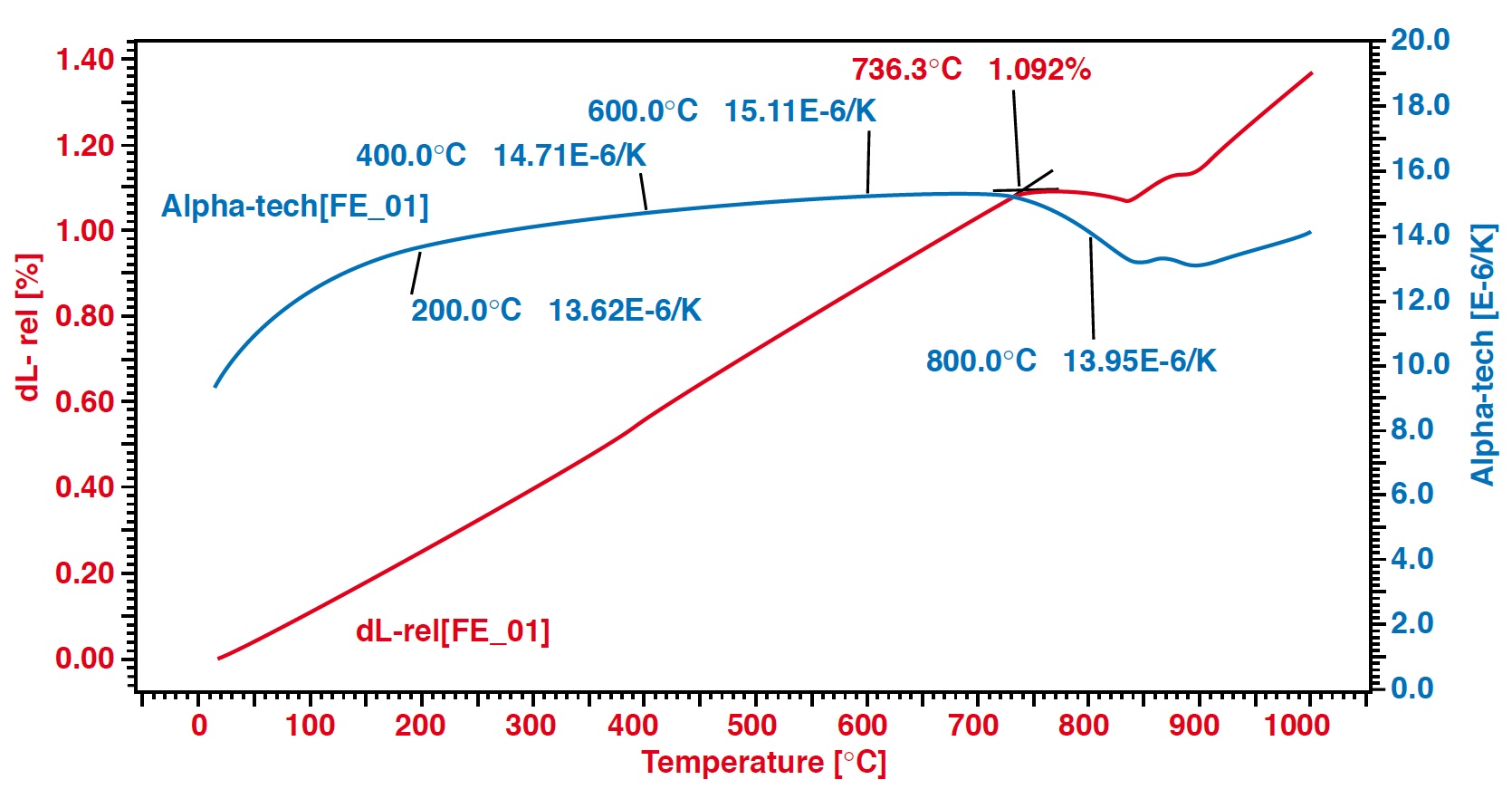

Application example: Iron

The linear thermal expansion (delta L) and the CTE of the iron sample under argon atmosphere are evaluated. The heating rate was 5K/min. After 736.3°C (peak temperature of CTE) shrinkage was detected, this is due to a change in the atomic structure, known as the curie-point. The difference of measured and literature result can be attributed to contamination of the sample.